-

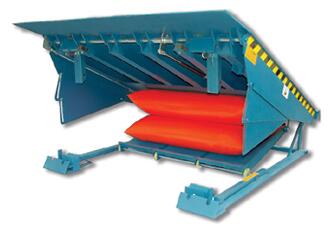

Kay has created a new kind of landing platform: an electric airbag landing platform. To provide customers with other unloading platform unparalleled "one button" mode of operation, easy to operate, affordable. The electric air bag type unloading platform integrates safety, firmness, stability and reliability. It can also reduce the customer's maintenance cost according to the design of the working environment.

The electric air bag type unloading platform relies on the principle of low pressure and high capacity filling. It can raise the surface rapidly through the expansion of the air bag, without the need of regular maintenance. The surface of the air bag is a high strength PVC fiber material. The design is reasonable, the working principle is simple, and the maintenance rate is reduced to the minimum. The utility model has the advantages of simple operation, low operation cost and improved work efficiency and safety of the unloading platform.

Platform material & surface treatment

The main parts are made of high strength steel plate and profile welding manufacturing pattern closely, table skeleton with special "I" made of steel, so that the surface stress is more uniform, and reduce the skeletonthe torsion, a 2 fold increase in load bearing capacity than the traditional channel, more durable. The steel structure is treated with strict shot blasting and rust removing. All steel components have been primed with two primers, two finishes, and high quality polyurethane finish. After drying treatment, the film thickness is not less than 0.08mm, and the standard topcoat is made of blue RAL5010.

-

Product structure and technical performance:

1 air bag is made of high strength PVC fiber materials imported from the United States has made preparation of durable nylon rib, even if the bag accidentally exposed, unloading platform can still work normally, but also quite easy to repair; all the materials have been common pest control and anti chemical corrosion.

2 the United States imported high speed blower roots blower (220V, current 10A, power 1.1KW), equipped with air filter cleaning and durable, effectively separating dust, and the return air its own automatic cleaning filter, and an electric motor protection. The equipment in extreme temperature -50 (-58 degrees Fahrenheit) to +65 (+150 degrees Fahrenheit) is still functioning.

3., the main mesa structure adopts the whole platform surface structure design, the surface adopts highly automatic welding tensile decorative plate table panel. The framework adopts the "I" steel support structure, which can effectively decompose the distribution of force and reduce the torsion of the skeleton, so it is more durable.

4.. The open loose leaf joint structure is made of high tensile figured steel plate and is connected by a high strength axle steel with a diameter of 25-30mm (1 "-1.2"). Compared with the traditional tubular welded joint, the open type loose leaf joint increases the welding area by 300%, and the force area increases by more than 2.5 times, so that the loose leaf binder increases the supporting force as high as 4 times, and is easier to maintain.

5., small and small pull the gravity push rod system, the use of the weight of the regulating plate, in the process of the introduction of loose leaf small pull, safe and stable. A gentle, smooth release during each operation prevents the loose leaf from hanging up at the highest point.

6., open base structure, easy to pit cleaning and routine maintenance.

7. power unit adopts motor, blower, no high pressure pump, etc. the introduction is reliable, safe and quick. The power unit is installed at the rear of the unloading platform bracket, and the installation position is higher than the pit plane, away from garbage and sundries.

8., power supply configuration, the United States imported high-speed blower (current 10A, power 1.1KW, 220V), installed at the back of the unloading platform bracket, adapted to cold, high temperature and other bad temperatures (-50 degrees +65 degrees Celsius).

9., the pit cleaning bag and its support are easy to move, and no need to use special tools to complete the daily cleaning of the blower and the irrigation of the pit.

10. control panel push button switch, easy to operate. Interlocking devices are installed between the berths to further enhance safety.

28 tons of 11 supporting legs structure patent design (60000lbs.) support leg structure in unloading process, when the truck suddenly left the platform unloading area, the supporting legs can make goods and keep the forklift in the horizontal plane, to minimize accidents, ensure the safety.

12. lower than the platform operation, can achieve the adjustment board below the platform of operation, (without extension of loose leaf small pull case), suitable for full load of low chassis truck first row of goods unloading.

13 anti pinch design of unloading platform on both sides of anti pinch foot guard, border with yellow / black stripes warning, even rose to the highest in the large area, but also to ensure the side of the side plate is completely closed, which can effectively avoid the risk of a bruised toe, can make the person, forklift, goods with full protection.

14. assembly, maintenance, support rod, unloading platform with assembly support rod, so as to support the unloading platform during equipment maintenance or pit cleaning, and ensure the safety of operation personnel on the platform.

15., floating adjustment, when loose leaf small pull in the end of the truck can be vertical deflection, the adjustment range is within 100mm (4).

16. front end of the anti-collision rubber unloading platform is equipped with two heavy duty anti-collision adhesive. The models are B300-250F, 250mm, x, 300mm (10, x 12).

Operating instructions: when the truck parked in place, the operator holding down the button on the control box, the work table is increased, and then through a small pull push rod system using a gravity adjusting plate, weight, in the process of falling out a small wrench loose. When the control button is released, the work platform of the loading and unloading platform is automatically lowered until the extension plate is lapped to the rear of the truck, and the loading and unloading operation can begin at this time. The operating range of the worktable is inside and minus 30mm. The standard extension plate has a length of 400mm. At work, the loose leaf binder exceeds the thickness of 100mm block 280mm and lapped at the rear of the truck. The design platform remains flush with a pit tail, effective compensation when loading and unloading carriage bottom slope was 100mm and the maximum guarantee is connected with the tail of the solid pit. Loose leaf small board can be retracted in case of collision.

-

The structure of technical performance of products: 1 air bag is made of high strength PVC fiber materials imported from the United States has made preparation of durable nylon rib, even if the bag accidentally exposed, unloading platform can still work normally, but also quite easy to repair; all the materials have been common pest control and anti chemical corrosion. 2 the United States imported high speed blower roots blower (220V, current 10A, power 1.1KW), equipped with air filter cleaning and durable, effectively separating dust, and the return air its own automatic cleaning filter, and an electric motor protection. The equipment in extreme temperature -50 (-58 degrees Fahrenheit) to +65 (+150 degrees Fahrenheit) is still functioning. 3., the main mesa structure adopts the whole platform surface structure design, the surface adopts highly automatic welding tensile decorative plate table panel. The framework adopts the "I" steel support structure, which can effectively decompose the distribution of force and reduce the torsion of the skeleton, so it is more durable. 4.. The open loose leaf joint structure is made of high tensile figured steel plate and is connected by a high strength axle steel with a diameter of 25-30mm (1 "-1.2"). Compared with the traditional tubular welded joint, the open type loose leaf joint increases the welding area by 300%, and the force area increases by more than 2.5 times, so that the loose leaf binder increases the supporting force as high as 4 times, and is easier to maintain. 5., small and small pull the gravity push rod system, the use of the weight of the regulating plate, in the process of the introduction of loose leaf small pull, safe and stable. A gentle, smooth release during each operation prevents the loose leaf from hanging up at the highest point.

6., open base structure, easy to pit cleaning and routine maintenance. 7. power unit adopts motor, blower, no high pressure pump, etc. the introduction is reliable, safe and quick. The power unit is installed at the rear of the unloading platform bracket, and the installation position is higher than the pit plane, away from garbage and sundries. 8., power supply configuration, the United States imported high-speed blower (current 10A, power 1.1KW, 220V), installed at the back of the unloading platform bracket, adapted to cold, high temperature and other bad temperatures (-50 degrees +65 degrees Celsius). 9., the pit cleaning bag and its support are easy to move, and no need to use special tools to complete the daily cleaning of the blower and the irrigation of the pit. 10. control panel push button switch, easy to operate. Interlocking devices are installed between the berths to further enhance safety. 28 tons of 11 supporting legs structure patent design (60000lbs.) support leg structure in unloading process, when the truck suddenly left the platform unloading area, the supporting legs can make goods and keep the forklift in the horizontal plane, to minimize accidents, ensure the safety. 12. lower than the platform operation, can achieve the adjustment board below the platform of operation, (without extension of loose leaf small pull case), suitable for full load of low chassis truck first row of goods unloading. 13 anti pinch design of unloading platform on both sides of anti pinch foot guard, border with yellow / black stripes warning, even rose to the highest in the large area, but also to ensure the side of the side plate is completely closed, which can effectively avoid the risk of a bruised toe, can make the person, forklift, goods with full protection. 14. assembly, maintenance, support rod, unloading platform with assembly support rod, so as to support the unloading platform during equipment maintenance or pit cleaning, and ensure the safety of operation personnel on the platform. 15., floating adjustment, when loose leaf small pull in the end of the truck can be vertical deflection, the adjustment range is within 100mm (4). 16. front end of the anti-collision rubber unloading platform is equipped with two heavy duty anti-collision adhesive. The models are B300-250F, 250mm, x, 300mm (10, x 12). Operating instructions: when the truck parked in place, the operator holding down the button on the control box, the work table is increased, and then through a small pull push rod system using a gravity adjusting plate, weight, in the process of falling out a small wrench loose. When the control button is released, the work platform of the loading and unloading platform is automatically lowered until the extension plate is lapped to the rear of the truck, and the loading and unloading operation can begin at this time. The operating range of the worktable is inside and minus 30mm. The standard extension plate has a length of 400mm. At work, the loose leaf binder exceeds the thickness of 100mm block 280mm and lapped at the rear of the truck. The design platform remains flush with a pit tail, effective compensation when loading and unloading carriage bottom slope was 100mm and the maximum guarantee is connected with the tail of the solid pit. Loose leaf small board can be retracted in case of collision.

-

Operating instructions: when the truck parked in place, the operator holding down the button on the control box, the work table is increased, and then through a small pull push rod system using a gravity adjusting plate, weight, in the process of falling out a small wrench loose. When the control button is released, the work platform of the loading and unloading platform is automatically lowered until the extension plate is lapped to the rear of the truck, and the loading and unloading operation can begin at this time. The operating range of the worktable is inside and minus 30mm. The standard extension plate has a length of 400mm. At work, the loose leaf binder exceeds the thickness of 100mm block 280mm and lapped at the rear of the truck. The design platform remains flush with a pit tail, effective compensation when loading and unloading carriage bottom slope was 100mm and the maximum guarantee is connected with the tail of the solid pit. Loose leaf small board can be retracted in case of collision.

Optional configuration:

1., according to customer requirements for design and manufacturing, non-standard production will increase product costs and delivery cycle.

2. provide integrated control systems, which work in conjunction with an industrial lift door or fast door, and achieve interlocking.

The 3. sides can be provided with rubber strips and brush seals to ensure the overall sealing performance of the unloading platform.

4. rubber barrier blocks or laminated anti-collision blocks can be fitted.

5., you can configure the color according to customer requirements.

6 unloading platform of small slab can be designed into a bevel angle, or auxiliary plate, meet different compartment size.