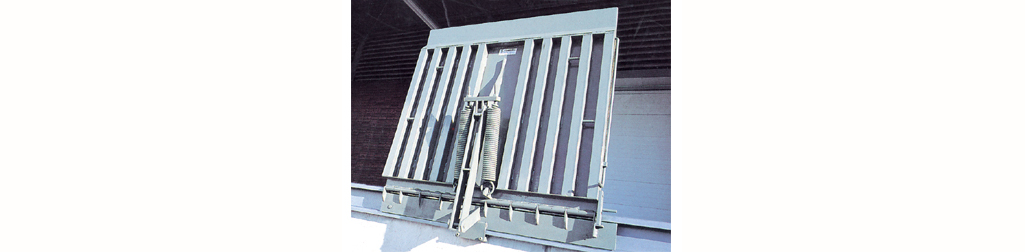

Tilting plate hydraulic platform is the most commonly used type, which can ensure the rapid and smooth handling of goods. When in use, lift the platform and the lip board first, turn the lip plate open, and then reduce the platform to the same height as the freight car. The preparations are in readiness for loading and unloading. Lift the platform, lower the lower lip and return the platform to its original position when the loading and unloading is complete. The installation method may be buried or suspended.

* main advantage: self cleaning hinge between platform and lip plate;

* lip length 400mm (optional 500mm)

A yellow black stripe warning tape is attached, which can be clearly seen when the platform is higher than the ground floor of the warehouse

* the surface of the platform is made of checkered boards to ensure the optimum attachment to the wheel of the forklift truck;

* the support of the lip plate ensures the safety of the platform when it is closed;

* hydraulic safety systems can quickly lock the platform when the hose bursts or the vehicle leaves suddenly;

* side guard plate can prevent the staff at work when he fell into the gap between the platform and the foot in the pit;

* maintenance support can ensure the safety of loading and unloading platform maintenance and maintenance.

For detailed technical information, please consult the manufacturer.

The structure of technical performance of products: 1 platform structure with surface structure design of whole platform, surface with high tensile strength of tread plate panel. The bottom frame of the panel adopts 6 unique I steel support structures, which can effectively distribute the force and reduce the torsion of the frame, so it is more durable. Table static load from 8 tons to the maximum 15 tons, dynamic load from 5 tons to 10 tons maximum. 2.. The open loose leaf joint structure is made of high tensile figured steel plate and is connected by a high strength galvanized axle steel. Compared with the traditional tubular welded joint, the open type loose leaf joint increases the welding area by 300%, and the force area is increased by more than 2.5 times, so that the loose leaf binder can increase the supporting force as high as 4 times. 3. hinge bolt design, skeleton minimum bearing capacity 50K, rear with 3 diameter 1 "hinge bolt, hinge built-in anti abrasion core. The 4. power unit is composed of an integral hydraulic system and a hydraulic pump station. 5. power configuration, we can provide two types of power configuration for customers to choose from: 380V/50Hz/0.75Kw and 220V/50Hz/1.1Kw, are equipped with built-in anti overload motor. 6. integral hydraulic system, the inner diameter of the main cylinder is 63mm (2-1/2), and the inner diameter of the auxiliary cylinder is 50mm (2). Suitable for 40 degrees Celsius (100 degrees Fahrenheit) ambient temperature. 7. the control panel is equipped with reset circuit, emergency brake button and LED marker light. 8. safety brake system is to ensure that in the course of loading and unloading, in case the truck suddenly left the loading and unloading area, the main platform stopped suddenly, to protect the goods on the platform. The safety braking system can be used again and again without debugging. The 9. emergency stop button can press the emergency stop button at any time to drive the solenoid valve in the hydraulic system, and the unloading platform will stop operating immediately. The operator does not need a long press button, and the platform will remain stationary as long as it is pressed. 10., floating adjustment unloading platform, large table can tilt with the vehicle. 11. vertical deflection, when loose leaf small pull up in the tail of the truck, can be vertical deflection, the adjustment range is within 100mm (4). 12. front end of the anti-collision rubber unloading platform is equipped with two heavy duty anti-collision adhesive. The models are B300-250F, 250mm, x, 300mm (10, x 12).